My contact person

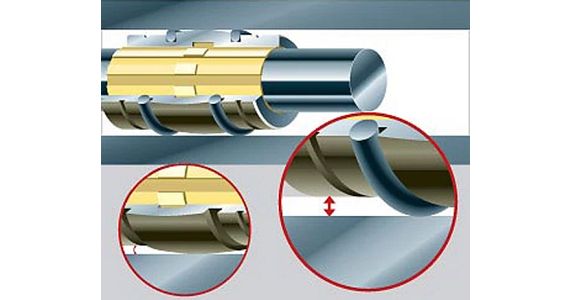

The drylin® R quad block is offered in open or closed type. In the open version, the linear carriage can be used for supported linear shafts.

Properties | Characteristics of igus® plain bearings | Characteristics of rolling bearings | Technical data of igus® plain bearings | Technical data of rolling bearings | Especially relevant for the following industries: |

|---|---|---|---|---|---|

| Precision | + | +++ | 0.02 - 0.15mm | 0.001 - 0.01mm | Machine tools, CNC processing, electronics manufacturing |

| Completely lubrication-free | +++ | + | Medicine, packaging, food, cleanroom, consumer goods | ||

| Maintenance-free | +++ | + | For many different branches of industry | ||

| Weight advantage | +++ | + | Aluminium approx. 2.7g/cm³ Polymer approx. 1.5g/cm³ | Steel approx. 7.8g/cm³ | Handling, automation, laboratory, leisure time |

| Highly dynamic responsiveness in the case of low loads | +++ | + | Packaging, handling, automation | ||

| Highly dynamic responsiveness in the case of high loads | + | +++ | Packaging, handling, automation | ||

| Stroke length variance | +++ | ++ | Camera technology, textile | ||

| Coefficient of friction | + | +++ | 0.15 - 0.3 µ | 0.001 - 0.05 µ | Manual adjustment, pivoting |

| Sensitivity to dirt | +++ | + | Packaging, stone, textile, paper, painting equipment | ||

| Noise dampening ¹ | +++ | ++ | 45 dB | 60 dB | Medicine, laboratory, furniture |

| Cost advantage | +++ | ++ | For many different branches of industry | ||

| Protection against corrosion | ++ | + | Filling systems, chemicals, food | ||

| Magnetism | + | +++ | Plastic, aluminium | Steel | Medicine, testing instruments |

| Chemical resistance | +++ | + | 1.4751 + iglidur® X | 1.4112 | Medicine, food, electroplating, filling systems |

| Compatibility of the modules | +++ | + | Jig construction, assembly line automation | ||

| Quiet operation without any vibration | +++ | ++ | Camera technology, inspection, medicine, 3D printer | ||

| Short-stroke suitability | +++ | + | Textile, handling | ||

| Easy to fit and quick replacement | +++ | + | Jig construction, assembly line automation | ||

| Rigidity | + | +++ | Machine tools, CNC processing, electronics manufacturing | ||

| Long travels of more than 10m | ++ | + | Camera, material handling, logistics | ||

| Temperature-resistant | +++ | + | up to +250 °C | Chemicals | |

| Smooth running | + | +++ | Manual adjustment | ||

| Maximum acceleration ² | +++ | ++ | 50m/s² | 15m/s² | Automation, handling |

| Maximum speed ² | +++ | + | 30 m/s | 5 - 10m/s | Automation, handling |